Weather Resistance

Outstanding weather resistance ability, color won’t be disseminated and faded in years when exposing to the air.

High Level

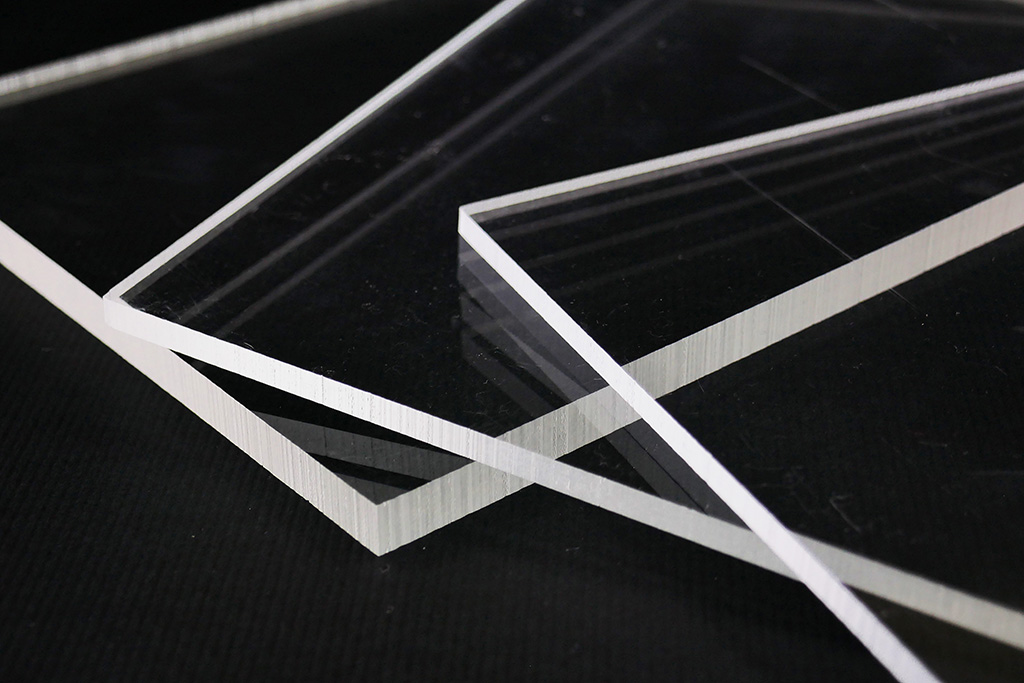

Clear Sheet

Clear sheet:Transmittance achieve over 92%.

Opal sheet:Obtained excellent efficiency in light diffusion.

Chemical Resistance

Excellent in chemical resistance property.

Stable physical property, suitable for any kinds of usage.

Excellent Processability

Light in weight and safer than glass. Easy to be formed.

Suitable for both mechanical processing and hot forming.

100%

Virginal PMMA

Our team of professionals in the areas of engineering, management and construction bring you the best product.

Producto

Podemos proporcionar una gama completa de especificaciones de 1,8 mm a 50 mm para tamaños y colores específicos de superficie transparente, opalina, fluorescente, mate, negro / blanco, azul / blanco, etc.

Join our team and enjoy a creative, dynamic and inclusive culture focused on one goal – improving the world around us through imagination and innovation.