CAST ACRYLIC SHEET PRODUCT

Properties |

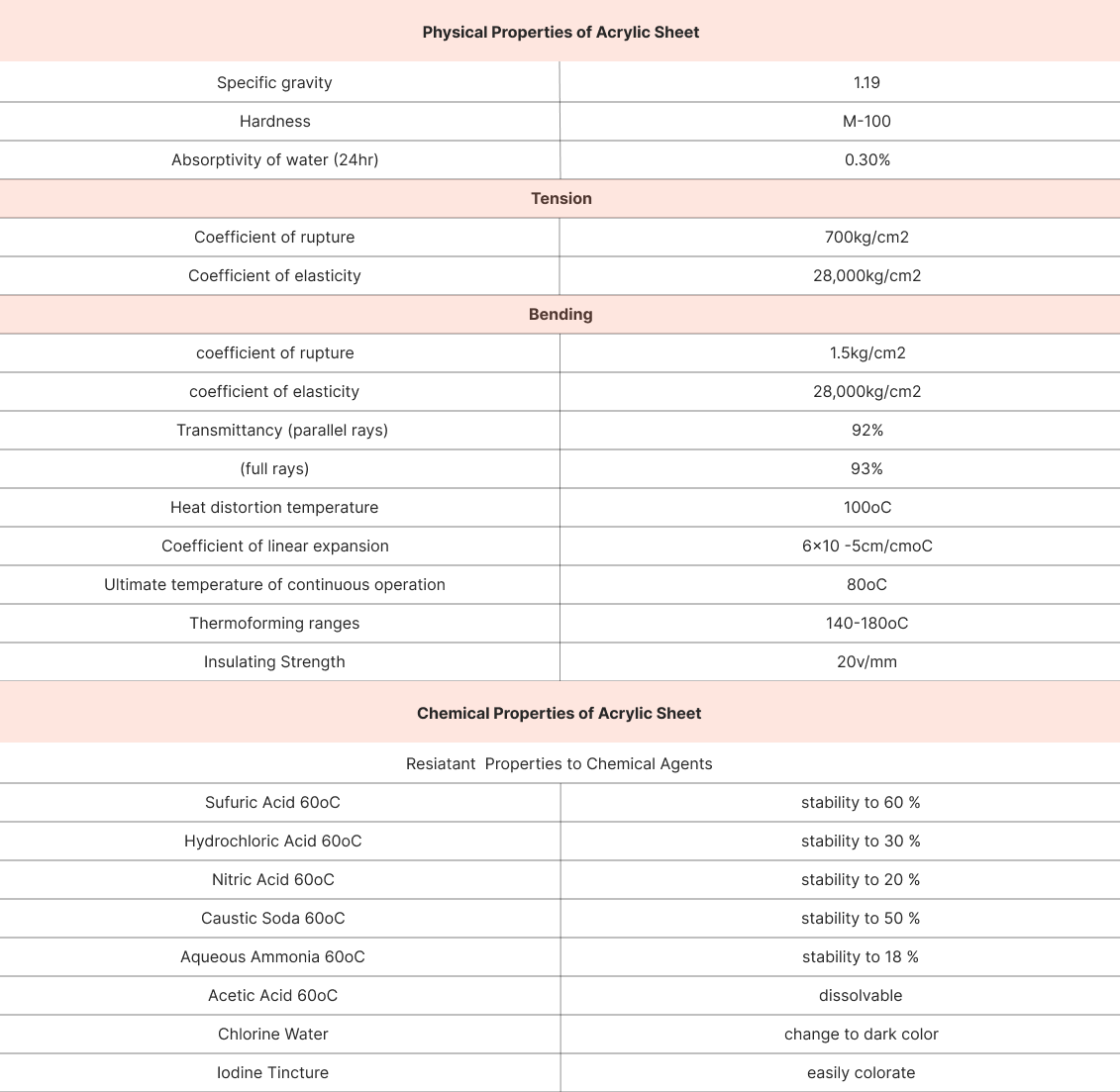

Acrylic sheets (PMMA) possess notable physical properties: a density of approximately 1.18 g/cm³, tensile strength between 8,000 and 11,000 psi, and flexural strength ranging from 12,000 to 17,000 psi. They offer excellent optical clarity with up to 92% light transmission and a refractive index 1.49. These characteristics make them ideal for signage, displays, and protective barriers.

For more detailed information, refer to our Product Properties and Product Specifications pages.

Are you interested in learning more about our acrylic sheet solutions or requesting a quote? Visit our Contact Us page to reach out to our team.

We're here to assist you with product specifications, custom orders, and inquiries.

FAQ :

What are the properties of acrylic plastic?

Acrylic plastic, commonly known as polymethyl methacrylate (PMMA), is a transparent thermoplastic renowned for its excellent optical clarity, transmitting up to 92% of visible light. It is lightweight—about half the weight of glass—and offers superior impact resistance, making it a durable alternative for various applications. Additionally, acrylic exhibits good UV and weather resistance, maintaining its properties even after prolonged exposure to sunlight.

What is the chemical composition of acrylic?

Chemically, PMMA is a synthetic polymer formed through monomer methyl methacrylate (MMA) polymerization. This results in a structure with repeating units characterized by a carbon backbone with pendant methyl and ester groups. This composition imparts PMMA with notable properties, including transparency, rigidity, UV light resistance, and weathering resistance.

What are acrylic's physical properties?

Acrylic plastic, or polymethyl methacrylate (PMMA), exhibits excellent optical clarity with up to 92% light transmission and a refractive index 1.49. It has a density of approximately 1.18 g/cm³, is about half the weight of glass, and offers superior impact resistance. Additionally, acrylic maintains its properties under prolonged exposure to UV light and weather conditions, making it suitable for various applications.

How do you bend acrylic?

Bending acrylic involves heating the material until it becomes pliable and then shaping it as desired. Standard methods include using a heat gun, strip heater, or hairdryer for thinner sheets. Once heated, the acrylic can be bent over a form or jig and held in place until it cools and retains the new shape.

How chemical resistant is acrylic?

Acrylic plastic (PMMA) exhibits moderate chemical resistance. It resists diluted acids, bases, and aliphatic hydrocarbons but is vulnerable to many organic solvents. For instance, it withstands 20% nitric acid exposure but is not resistant to substances like methanol or acetone. Therefore, it's crucial to consult a chemical compatibility chart to ensure acrylic's suitability for specific chemical exposures.